MineGlow features in National Resources Review

MineGlow shines a light on safety in hazardous mining and oil & gas environments

Inadequate lighting and electrical light failures pose a major safety risk to hazardous mine and oil & gas operations.

Poor illumination is still a leading cause of workplace accidents, significantly impacting worker fatigue, attention, reaction ability and hand-eye coordination.

This is common in underground mining environments where poorly lit conditions also increase the risk of physical hazards such as slips, trips and falls.

Lights are also one of the most common causes of explosion ignition in high-risk, volatile combustible oil and gas and petroleum environments.

Australian-based industrial lighting pioneer MineGlow is helping a growing number of mining, tunnelling and oil and gas clients address these challenges to make workplaces safer, brighter and more productive.

The rise of LED strip lighting

Over the past decade, LED lighting has been widely embraced by the mining and resources sector, as a cost effective, low maintenance alternative to standard lights.

Demand continues to rise as more industrial operations make the switch to strip, seeing tangible benefits in efficiency, sustainability, safety, installation and maintenance.

The benefits over traditional light sources, such as florescent or LED tube, or spotlights, are now well known. Common concerns include their need for regular replacementꟷ traditional lights are easily knocked and brokenꟷoverall reliability, longevity and efficiency.

MineGlow leverages advanced LED lighting technology to make harsh industrial environments brighter, safer and more productive in several ways:

High visibility improves safety and early detection

Getting the right level of illumination for your environment is critical, whether your workforce is operating underground or in hazardous, volatile conditions.

In environments where there is no natural light, like underground mining, workers need ‘daylight’ conditions to see what’s going on around them and to support their health and wellbeing.

MineGlow’s x-Glo LEDs provide continuous, floor-to-ceiling illumination that eliminates glare and hazardous dark spots and creates full daylight conditions. This helps miners to work more safely and efficiently, while mitigating the risk of hazards.

For example, high visibility is essential to the early detection and prevention of conveyor damage. MineGlow’s x-Glo continuous strip lighting meets this need, helping workers detect any early signs of tears or damage to the conveyor. Lighting is installed overhead and/or on the side of the conveyor for the visibility and early detection of damage or obstructions.

Picture 1: Before and after: installation of MineGlow’s LED strip lighting at QLD underground mine

In mining and oil & gas environments, both the colour and output of lighting are essential to ensure that mine workers can operate safely and productively. For example, MineGlow’s x-Glo strip lighting produces 65000k white light emissions for precise colour recognition, which is critical when working with wiring.

Industrial-grade LED strip lights are also highly flexible, providing different levels of illumination and colours to fit the mining application, work zone and general operating conditions.

Eliminating the risk of explosion

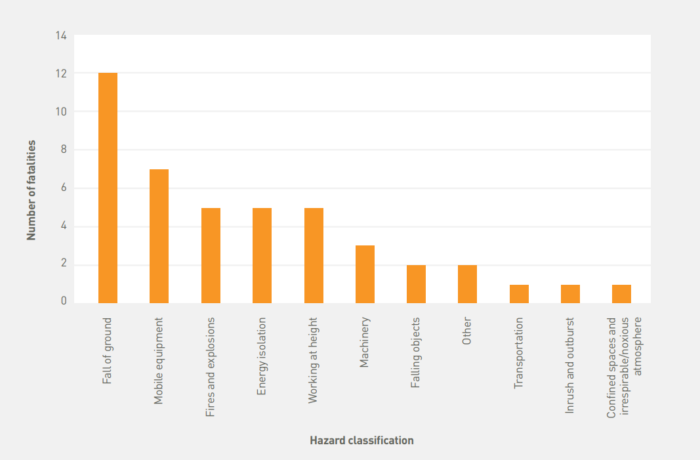

Electrical hazards on mine sites can be lethal. Fire and explosions are the third-highest cause of fatalities globally, as reported in the International Council on Mining and Metal’s (ICMM) 2020 Safety Performance Report.

Lighting is one of the most common causes of explosion ignition. The best way to minimise explosions in high-risk industrial areas is to remove potential ignition sources.

Figure 1. Associated hazards attributed to fatalities in 2020

In highly explosive or combustible environments, electrical failures in lights should result in either immediate isolation of the spark through encapsulated lighting or non-sparking such as intrinsically-safe lighting fixtures.

Last year, MineGlow introduced the world’s first IECEX and ATEX certified explosive-proof LED strip lighting in Oceania approved for Gas Zone One and Two and Dust Zone Twenty-one and Twenty-Two.

The explosive-proof solution minimises risk by isolating and containing sparks within the strip to prevent explosions from escaping and potentially igniting the gases and particles in the atmosphere.

MineGlow’s X-Glo lights are fully encapsulated with silicone, making them resistant to dust, humidity, chemicals and extreme environmental temperatures without enabling the risk of an explosion.

Reducing costs and installation time

Due to their low-profile design, strip lights are easy to position and install in any location, making them less likely to be damaged by underground mining equipment. They provide a flexible solution for installing and positioning lighting in the best place for the task at hand such as lighting near any potential hazards like steps or ramps.

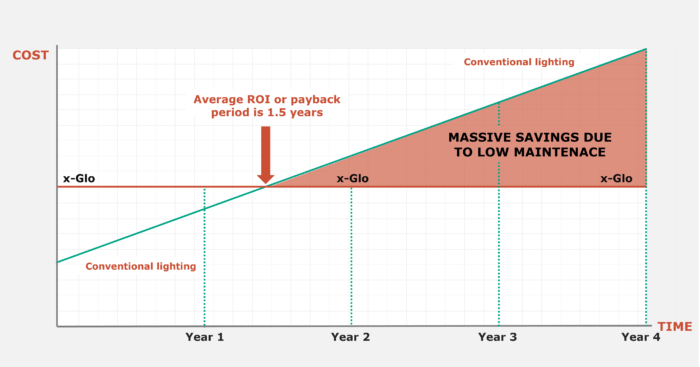

There are no labour costs to replace or maintain, and just about anyone can install them quickly and easily. As a result, MineGlow’s x-Glo strip lights deliver significant costs savings and full return on investment within two years.

Figure 2. x-Glo LED strip lighting provides a cost efficient, long-term sustainable solution over time.

MineGlow is the only provider in Australia to offer a long-range solution, enabling mine sites to install continuous lengths of up to 168 meters between power sources.

This simplifies installation and reduces the base infrastructure needed to power the lights. This results in less parts that can fail or get damaged resulting in next to zero maintenance.

MineGlow’s long-range LED strip lights are also gaining momentum in the tunnelling sector, reducing infrastructure and cost due to the need for fewer power sources over long distances.

Driving efficiency and sustainable outcomes

LED strip lights deliver substantial cost savings, as they don’t require as much electricity to run. They provide an energy efficient, long-term sustainable solution by reducing your running costs and environmental footprint.

MineGlow’s x-Glo strip light solutions have a lifespan of up to ten years with only a 20 to 30 percent loss of luminescence over this period, even in the most challenging environments.

They are powered with 24V, 36V or 48V (AC or DC), giving customers the option to choose the optimum level of illumination for their application while maximising workforce safety, productivity and wellbeing.

Supporting early warning and evacuation systems

LED strip lighting is a popular solution for emergency lighting and emergency evacuation directional lighting. In an emergency, lighting must be robust and reliable, for effective operation in the case of a power failure.

MineGlow’s emergency evacuation system is a recent innovation that directs underground workers to safety in emergency evacuations.

When the system is activated it provides consistent directional pulses of lights throughout an entire network of underground tunnels ensuring all occupants are informed instantaneously of an emergency and the direction for evacuation to designated exits or areas of safety.

Available in any colour and pulsing configuration, the chasing system suits different applications and risk zones, offering high sight impact, visibility and reliability when it matters most.

The cost-effective, environmentally-friendly emergency lighting system operates on high sight impact, rather than sound, making it perfect for machine operators, with excellent visibility in smoke filled or low light conditions.

Powered by x-Glo strip lighting, directional lighting prevents workers from entering into specific dangerous environments to maximise safety, suppress panic and provide comfort in a high-stress, dangerous environment.

It integrates with existing infrastructure and can be easily installed in an entire or partial network of underground tunnels with various activation points.

In a recent installation at a gold mine in Ghana, West Africa, MineGlow’s directional strip lighting improves underground visibility and directs workers to their nearest escapeway in case of an evacuation. MineGlow’s x-Glo lighting is also installed inside the twelve modular escapeways, which are fully enclosed polyurethane ladder tubes. Directional lighting plays a vital role at the site, helping staff to find their nearest escapeway when visibility is compromised.

Making the switch to strip

Before making the switch to strip, there are a number of important factors to check when selecting the appropriate LED strip light solution for your industrial environment.

There is no ‘one-size-fits-all’ when it comes to LED strip lights. There are many variations in product quality and a wide range of specifications to meet the electrical certification requirements for different operating zones in mining, and oil & gas.

This is critical when working in volatile environments with extreme temperatures, explosive gases, combustible dusts, corrosive fluids and high vibration.

While specifications will vary in importance depending on your specific application, key considerations include:

- Component quality and reliability

- Lumen output (brightness)

- Ingress Protection (IP) ratings

- Water, dust and chemical resistance

- Fire retardant, impact and shock resistance

- Pulling power

- Explosion protection

- Installation and maintenance time and cost

- Length and input power supply

- Lifetime operation and warranty

As the global market for LED strip lighting becomes more competitive, making the correct choices for your environment and application is paramount. Get it right and you will improve light quality, visibility and the health and wellbeing of your workforce. You will create a safer, brighter and more productive place for your employees to work, while increasing efficiency, sustainability and reducing operating costs.