How hazardous area lighting improves underground mine safety

MineGlow features in the May issue of Safety Solutions discussing the importance of having the appropriate lighting in hazardous areas.

Read the article and learn how hazardous area lighting the MineGlows LED strip lighting is improving underground safety.

Lighting is one of the most common causes of explosion ignition in high-risk mining environments while inadequate lighting and electrical light failures pose major safety risks to hazardous mines. In 2020, the International Council on Mining and Metals (ICMM) reported fire and explosions as the third-highest cause of fatalities globally1.

Ensuring your hazardous area lights meet the highest local and international safety standards and certifications is paramount to keeping your workforce safe, while improving light quality and visibility, maximising productivity and reducing operating costs.

Exposing the dark side to inadequate lighting

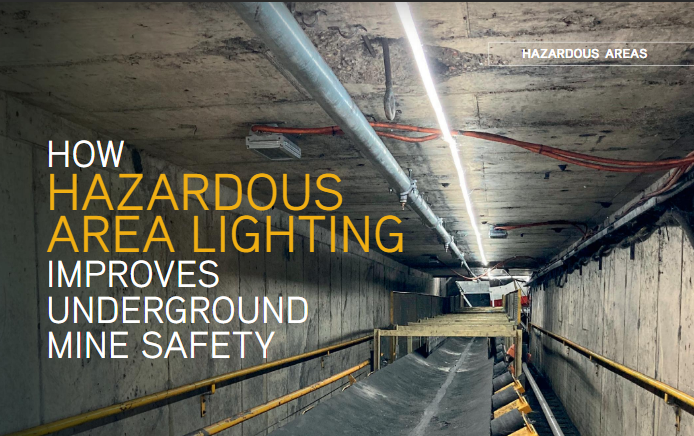

Many underground coal mines continue to operate with inadequate lighting in hazardous underground areas like coal wash plants, reclaim tunnels and conveyor systems where flammable gases are present.

In many cases, coal wash plants and reclaim tunnels are positioned underneath coal stockpiles and are at risk of fire and explosion because of the potential build up of methane gas and coal dust due to coal transportation.

Because reclaim tunnels serve as the main transfer point from coal stockpiles to other areas within the mine, appropriate lighting is paramount.

In addition to the possibility of explosion ignition, traditional lighting sources, like fluorescent lighting, poses serious health and safety risks. The inadequate distribution of lighting increases the likelihood of slip and trip hazards and makes it more difficult to detect any damage to conveyor systems and other vital equipment, further compromising safety, visibility and productivity.

The rise of LED strip lighting

There has been a rising demand for linear lighting systems, like LED strip lights, that provide a continuous illumination, in often hard to reach places. While explosion-proof LED strip lighting solutions are becoming a safer, more cost-efficient solution to alternative complex lighting infrastructures in hazardous areas.

In highly explosive or combustible environments, electrical failures in lights should result in either immediate isolation of the spark through encapsulated lighting or non-sparking such as intrinsically safe lighting fixtures.

Industrial grade LED strip lights prevent explosions from escaping and igniting gases, dust, fibres and particles in hazardous atmospheres by isolating and containing sparks.

When selecting any new hazardous area lighting fixture, ensuring your lights meet the highest local and international safety standards and certifications is paramount. Some important features to look out for include:

- IECEx and ATEX certified

- IP65 or higher

- Robust and durable design to withstand extreme temperatures

- Corrosion resistance

- Impact and shock-resistant outer shell

- 80+ colour rending index

Explosion-proof LED strip lights in action

Last year, leading provider of industrial grade LED strip lights MineGlow introduced the world’s first IECEX and ATEX certified explosive-proof LED strip lighting in Oceania approved for Gas Zone One and Two and Dust Zone Twenty-one and Twenty-Two.

The explosive-proof solution minimises risk by isolating and containing sparks within the strip to prevent explosions from escaping and potentially igniting the gases and particles in the atmosphere.

Fully encapsulated with silicone, the lighting system is resistant to dust, humidity, chemicals and extreme environmental temperatures without enabling the risk of an explosion.

MineGlow partners with mines across Australia, most recently working with a Queensland underground coal mine to improve visibility and safety of their reclaim tunnel.

The installation of the MineGlow Exm range enabled the mine to significantly improve the health, safety and wellbeing of site personnel working in the tunnel. The solution also improved inspection and maintenance time due to the increase in illumination throughout the reclaim and wash plant tunnel.

Download the case study here.

About MineGlow

MineGlow introduced the world’s first industrial-grade LED strip lighting solution for hazardous mining environments in 2014. Meeting the growing need for robust, energy-efficient lighting alternatives in other harsh industrial sectors, MineGlow has expanded its presence with the widest range of purpose-built, fully customisable LED strip light solutions for mining and energy, tunnelling, construction, manufacturing, marine ports and conveyors.

MineGlow transforms high-risk oil and gas rigs, coal mines and other industrial applications into brighter, safer and more productive places to work, while reducing energy and operating costs.

[1] International Council on Mining and Metals (ICMM) 2020 Safety Performance Report