Research & Development

LUMINOUS EFFICACY TESTING

Every strip is tested to make sure the right amount of luminosity as specified.

CONNECTOR WEIGHT TEST

All connectors are subjected to weight testing to ensure they are up to the rigorous conditions they will be subjected to.

HUMIDITY TESTING

This test is used to determine the longevity of all components in a high humidity environment.

CORROSION IMMERSION TESTING

Thorough testing is done with the use of industrial chemicals, including Acid, Petrol,Salt Water in atmospheric conditions.

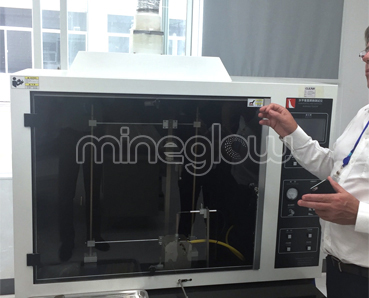

FIRE RETARDANT TESTING CHAMBER

All strip lighting is tested to ensure that the PVC used is fire retardant and non toxic.

24 HOUR CONSTANT TESTING

All strip lighting is constantly tested 24 hours 7 days a week to monitor any signs of drop in luminescence,PVC deterioration and longevity.

This testing has been done non stop over the last 5 years.

IP TESTING CHAMBER

Testing is carried out to determine the IP Rating by pressure and depth the strip is exposed to.