Explosion Proof Lighting for Hazardous Environments

Explosion Proof Lighting

Mineglow’s EXM Range of explosion proof LED lighting is engineered for safety, efficiency, and compliance in the most dangerous industrial settings. Whether in oil and gas facilities, underground mines, chemical plants, or wastewater treatment plants, our lighting solutions prevent ignition in hazardous atmospheres whilst reducing fatigue, eye strain and protect workers around the clock.

Certified to both IECEx and ATEX standards, Mineglow’s luminaires combine innovation with peace of mind, delivering:

- Safety & compliance for hazardous areas (Zone 1, Zone 2, Class 1 Division 2).

- Energy efficiency that reduces operating costs.

- Long life LED technology designed for reduced maintenance.

- Reliability in dust, vibration, gas, and extreme temperature conditions.

Mineglow provides more than just lights – we deliver explosion proof lighting solutions that allow hazardous facilities to operate more safely, efficiently, and confidently.

Why Choose Explosion Proof LED Lighting?

Unlike standard light fixtures, explosion proof lights are designed to contain sparks, heat, or arcs that could otherwise ignite flammable gases, dust, or vapours.

With Mineglow, you gain:

Safety and compliance

Shadow Free Lighting

No dark spots or shadows making it easier to work and move around. Reducing fatigue and eye strain.

Reliability in harsh environments

Built in C-Mask™ Technology to resist dust, chemicals, vibration, and extreme temperatures.

Efficiency

Our industrial explosion proof lighting range delivers unmatched safety while supporting operational efficiency.

The EXM Explosion Proof LED Product Range

Explosion Proof LED Luminaires

Our core product line of explosion proof luminaires provides consistent, high-quality shadow free illumination in hazardous areas.

Designed for industrial environments with explosive atmoshepres present; these LED fixtures ensure safe use across multiple industries.

Explosion Proof Flood Lights

Mineglow’s LED flood light hazardous area solutions provide powerful, wide-area illumination where visibility is critical. Ideal for processing plants, Zone 1/2 facilities, and Class 1 Division 2 hazardous locations, these blast proof lights perform even in extreme conditions.

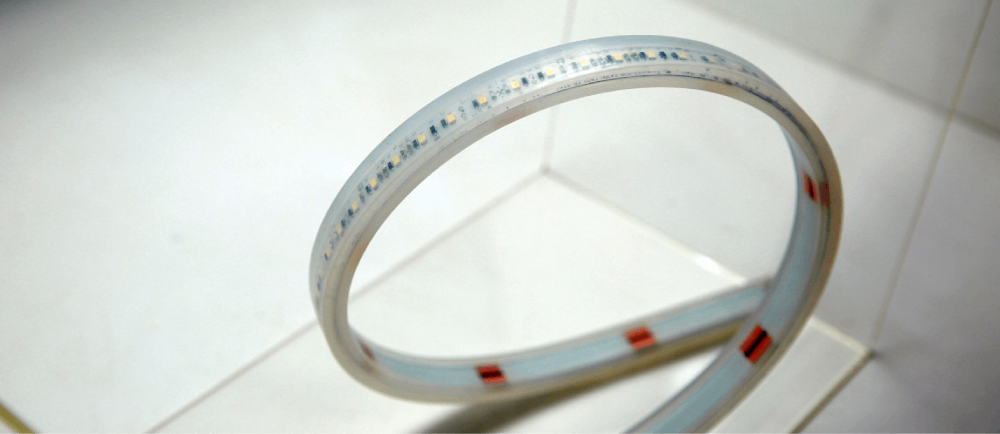

Explosion Proof LED Strip Lights

Our specialty lies in LED strip lights for hazardous areas. Flexible, customisable, and IECEx & ATEX certified, these strips are trusted in oil, gas, mining, and wastewater treatment plants. They are designed to reduce fire hazards, support long continuous runs, and deliver cool white, energy-efficient light.

- SafeGlo™ – Engineered for Oil & Gas, tank storage, granaries, distilleries and water treatment facilities.

- x-Glo – Engineered for underground coal mines and hard rock explosive storage magazines.

Various voltage options:

Emergency and Exit Explosion Proof Lighting

Mineglow has developed its own explosion proof emergency lights and explosion proof exit lighting systems to keep facilities compliant with escape route regulations. These systems are critical for worker safety during power outages, ensuring safe evacuation without risk of ignition.

Explore our range

Are EXM LED Strips an Alternative to conventional fixtures?

When people search for explosion proof LED fixtures or an explosion proof LED light fixture, they’re usually thinking of traditional bulky housings designed for hazardous environments. While these conventional fixtures are widely used, Mineglow’s EXM Range offers a more advanced solution.

Unlike standard fixtures, the EXM is not a single bulky light. It is a certified continuous LED strip lighting system engineered for hazardous areas. This design delivers the same safety compliance but with key advantages:

Flexibility

EXM strips can be customised in length (from 17 cm up to 30 m), making them adaptable to tanks, tunnels, conveyors, walkways, and any confined spaces.

Longer continuous runs

Instead of multiple individual fixtures, EXM allows extended runs of safe, consistent illumination with fewer breaks. Up to a 47% in cost reduction

70% Reduction in Maintenance

An 30m EXM strip typically replaces up to 10 conventional lights and power supplies. This means less parts to service and maintan. Saving money, time and less production downtime.

Energy efficiency

Designed for hazardous locations, EXM strips use advanced LED technology that reduces energy consumption by up to 80% vs. conventional fixtures.

So while Mineglow’s EXM range is not a traditional explosion proof LED fixture, it is a modern, certified alternative that delivers safer, more efficient, and more versatile lighting for hazardous environments.

Certified for Hazardous Zones

The EXM Range is tested and approved to meet both IECEx and ATEX standards. Suitable for:

- Zone 1 & Zone 2 hazardous areas

- ATEX Zone 2 LED lighting

- Facilities requiring IECEx & ATEX approved led lighting

Every product has full certification, available on request, for safe installation in hazardous environments.

Applications of Explosion Proof Lighting

Oil and Gas Industry

Safe illumination for oil refineries, offshore rigs, and processing plants where flammable gases and vapours pose constant risks. Mineglow provides energy efficient lighting for oil and gas that enhances safety while reducing operational costs, making it the preferred choice for hazardous offshore and onshore facilities.

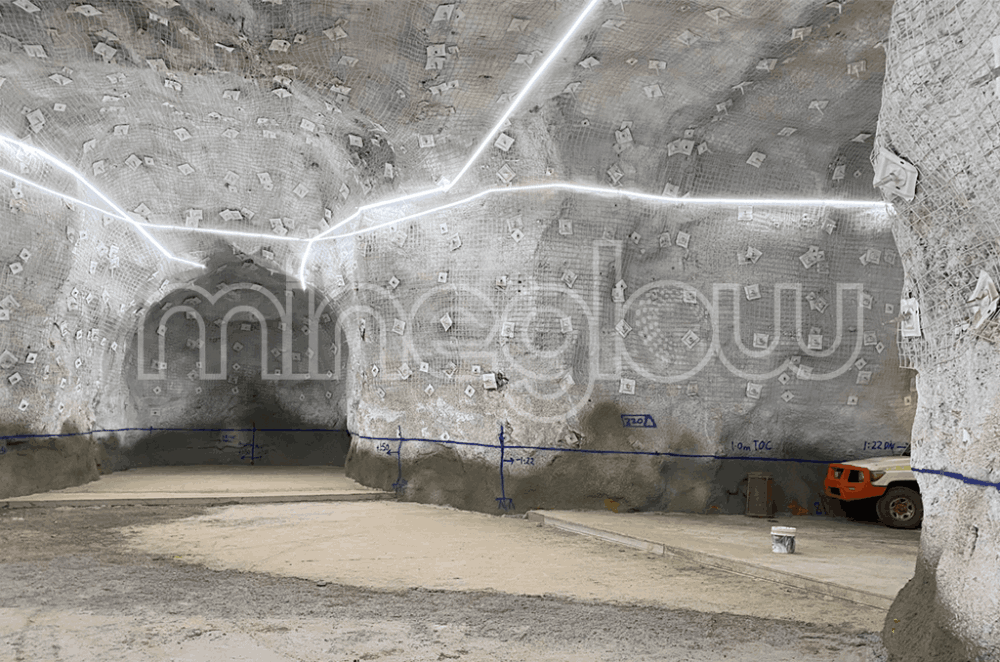

Mining and Tunnels

Built for underground mine lighting and tunnel operations, our EXM products withstand dust, vibration, and extreme temperatures. Our 36V explosion proof lighting is particularly suited to coal mines and heavy industry.

Chemical and Industrial Facilities

Reliable visibility where dust, vapours, and explosive particles are present. Our industrial explosion proof lighting supports safe operation in chemical plants, wastewater treatment plants, and manufacturing facilities.

Applications

| CLASS 1- GASES ZONES 1-2 | CLASS 2-DUST ZONES 21-22 |

|---|---|

| SUBSTANCE FLAMMABLE GASES, VAPOR OR LIQUIDS Acetylene, Hydrogen, Ethylene, Propane | SUBSTANCE COMBUSTIBLE DUSTS Conductive dust, non-conductive dust, combustible flyings |

| TYPICAL ENVIRONMENT ✓ Oil & Gas drill rigs ✓ Oil & Gas production platforms ✓ Oil & Gas floating production ships (FSPO's) ✓ Product Distribution Terminals ✓ Liquid natural gas ships ✓ Liquefaction terminals ✓ Regasification terminals | TYPICAL ENVIRONMENT ✓ Underground coal mines ✓ Surface coal mines ✓ Industrial & storage facilities ✓ Grain silos ✓ Paint factories ✓ Paper & textile mills |

Technology and Design Features

Every MineGlow EXM product is built to deliver increased safety with flexible mounting options for walls, ceilings, and poles. Key features include:

- Non-sparking design for ignition control

- Energy efficiency with long life cycles

- Reduced maintenance for lower operational costs

- Suitable for extreme and harsh conditions

Exceptional lighting for Explosive environments

Both the SafeGlo and x-Glo Exm series is an innovative line of LED hazardous area lighting, specifically designed for use in potentially explosive atmospheres (Zone 1/21 & 2/22) within harsh industrial settings such as coal mines and oil & gas facilities. Our Explosion Proof Strip Lights are designed to provide a reliable and safe lighting solution that provide continuous area and shadow free lighting.

Flexible by design. Flexible by nature.

The MineGlow Exm IECEx LED strip lighting series deliver a highly flexible and customisable solution where explosion proof lighting is required where highly flammable and explosive substances are present.

- Available in 24, 36 and 48v DC options

- Providing brightness options from 1000 to 400 lumens per meter

- Select the length you need from 17cm up to 30 meters

- Select the voltage, level of brightness and length needed for your work zone

Australian certification number IECEx TSA 21.0013X with the following markings:

- Ex mb I Mb

- Ex mb IIC T6 Gb

- Ex mb IIIC T80°C Db -30°C ≤ Ta ≤ 80°C

Why Choose Mineglow?

As an Australian hazardous area lighting specialist, Mineglow has a proven track record of supplying safe and reliable industrial explosion proof lighting solutions for over 10 years!

- Pioneers of LED Strip Lighting for hazardous environments

- Trusted by leading oil & gas, mining and tunnel operators

- Simple lighting solutions tailored for complex hazardous environments

- Reputation for safety, compliance, and ‘fit for purpose’ products

FAQs about Explosion Proof Lighting

What is explosion proof lighting?

What is the difference between explosion proof lights and standard LED lights?

Standard LED lights are not built to contain a potential spark occuring from within the fixture and enter the explosive atmosphere. Explosion proof LED lights are sealed in such a way as to contain any potential ignition or spark and require certifications to operate in a hazardous location.

Where are explosion proof emergency exit lights required?

They are required in any hazardous facility to illuminate the escape way to guide them to safety.

Do explosion proof strip lights replace exit signs?

No. They provide pathway illumination along and used alongside certified exit signage.

What industries use explosion proof lighting?

Explosion proof lighting is typically used in any area that has the following present:

- Flammable gases or vapors

- Combustible dust

- Volatile chemicals

Most commonly used in oil & gas, mining, granaries, distilleries, fuel storage facilities, paint shops, tankers, tunnelling, wastewater treatment, and chemical processing plant

How long do explosion proof LED luminaires last?

With proper installation and operated within the specifications of the explosion proof light, they can last over 50,000 hours, reducing maintenance and replacement costs.

Can explosion proof lights operate in extreme temperatures?

A light is certified as to what what ambient operating temperatures it can operate safely.

Mineglow’s explosion proof LED lights are designed to operate in ambient temperatures between -30˚ to +80˚ Celsius. It is also protected with C-Mask™ to repel dirt, dust and chemicals to withstand harsh environments.

What does ATEX certified LED lighting mean?

ATEX certification for lighting refers to compliance with a set of European Union regulations that ensure lighting used in explosive atmospheres is safe.

ATEX certified LED Strip lighting is rated as follows to ensure safe operation:

- Zone 0: Continuous presence of explosive atmosphere (highest risk)

- Zone 1: Likely presence of an explosive atmosphere during normal operations

- Zone 2: Unlikely presence, and if it occurs, it’s short-lived

What does IECEx certified LED lighting mean?

IECEx certification for lighting means the product complies with the International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres.

Similar to ATEX, but IECEx is globally recognised, not just within the EU.

LED Lighting is rated based on the environment it can safely operate within:

- Zone 0: Continuous presence of explosive atmosphere (highest risk)

- Zone 1: Likely presence of an explosive atmosphere during normal operations

- Zone 2: Unlikely presence, and if it occurs, it’s short-lived

Contact Us for Explosion Proof LED Solutions