Underground Mining Light: Five Imperatives

Underground mining light has fundamentally changed how we illuminate harsh and hazardous underground mining environments. Technology is evolving rapidly in this space, as new solutions continue to drive improvements in quality, safety, installation and maintenance.

Top 5 imperatives of industrial underground mining light

1. Not all underground mining lights are created equally

Product design varies greatly in underground LED lighting so buying from a reputable partner is vital. Make sure your underground mining lights are industrial-grade quality and approved for use in underground mines.

Check your certifications to ensure your LED strip lights have been independently tested, meet the highest local and international safety standards. They are fully certified to perform in harsh and hazardous conditions.

For example, Mineglow offers the only ATEX certified LED strip light available for coal mines.

Look for LEDs that have been rigorously tested for durability and are waterproof (IP 67), fire retardant and self-extinguishing, impact-resistant and shock-resistant. Premium-quality solutions are also blasted resistant and explosion-proof (IECEX certified). Also, it can withstand 70kg of pulling power.

Ensure that dust and dirt retardant properties come as standard for all your LED strip lighting.

2. Lumens and lifespan

Compared with early LED designs, today’s best-LED strip lights offer higher lumen outputs per watt and increased lifespan. High-quality, underground mining lights do not fail like fluorescent lighting. They use significantly less electricity, resulting in immediate and ongoing savings in running costs.

Eliminating the risk of blackouts, underground mining light output gradually decreases over time. This allows for a regular maintenance schedule and replacement before failure for greater consistency of lighting. It also improved peace of mind and safety for underground workers.

Mineglow LED strip lighting systems use specialized components to withstand continuous operation. Compared to other solutions, Mineglow LEDs function at optimal efficiency for long periods. You can expect high-quality, LED solutions to deliver a lifespan of five to ten years with only a 20 to 30 per cent loss of luminescence during this period and a five-year warranty period.

3. Clear and simple

Underground mining light products have to be resilient and reliable. Mining operations are supported by a lighting industry whose technological advances improve cost-effectiveness and safety. Expect top-quality underground mining lights systems, clear illumination for underground mines at half the wattage and a fraction of the installation time and cost of traditional lighting systems.

High-quality underground mining light should deliver a complete flood of lighting from the floor to ceiling to create daylight working conditions. Constant luminescence is important to eliminate spots. It reduces threats of glare and blinding, reduces preventable incidents and improves efficiency.

Traditional fluorescent lighting creates a wide and broad dispersion of light. It generates spill light that can contribute to reflection or glare off PPE cap shields. In comparison, Mineglow LED Strip lighting is directional where 100 per cent of the light emission from the LED is directed onto the task area. Moreover, it maximizes lighting efficiency, minimizing spills and reducing the instances of glare.

The white light emissions from a Mineglow LED strip lighting source also allow for more precise colour recognition. This provides a strong contrast to black backgrounds and a high perception of illuminance.

Always choose industrial-grade LED strip lighting that’s purpose-built for maximum illumination and visibility, fast deployment and zero maintenance.

4. End-to-end power supply

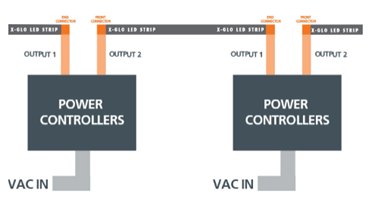

The quality of your power supply is critical to the performance of LED lights. Built-in power redundancy is a unique feature that allows for the connection of a power supply at both ends of the strip lighting. This essentially doubles the rated length. Also, it allows the lighting to continue to operate even if completely severed, or if one of the power supplies fails.

Choose LED strip lighting that can be manufactured to suit your power specifications using 24, 36, 48-Volt AC or DC power. Mineglow LED power controllers to convert the input voltage from 110/240 VAC into a lower voltage of 12, 24 or 36 VDC to energize the LEDs. The power controllers have a variable input feature. So, it can manage any voltage from 85 to 265VAC and making it suitable for applications worldwide.

5. Know your installation environment

Understanding your installation environment is also critical to selecting the right LED strip lights. With a wide array of standard, long-range and specialist product lines and colours now available, it’s important to select the right solution designed for your operating environment, unique risks and hazards.

For example, there is strong demand for customized lengths and longer LED strip run lengths that support long-range applications. Mineglow strips can customize for any length. Also, it offers the longest continual run lengths in the LED strip market – including the only LED light strip that can be run for continuous lengths up to 168 meters. Moreover, Robust and reliable power controllers placed at key intervals prevent voltage drop and ensure consistency of brightness along the strip.

Mineglow’s emergency LED pulse system is a recent innovation that guides underground workers to safety in emergency evacuations. Available in multiple colours, the chasing system suits different applications and risk zones, offering high sight impact, visibility and reliability when it matters most.

The underground mining lights market is continually improving as advances in technology. It delivers new and innovative solutions in mine rescue, self-escape and emergency lighting while enhancing overall product life, length and colour. Expect to see more innovation from LED market leaders to further improve underground safety, productivity and efficiency.

_____________________________________________________________________________

About Mineglow

Lighting the way for zero harm

Mineglow transforms high-risk industrial work environments into brighter, safer and more productive places to work while reducing operating costs. Specializing in high quality, high-performance solutions for the world’s toughest environments – underground, inland and offshore – Mineglow’s brand promise is simple: Maximum visibility and protection for zero harm.

Mineglow introduced the world’s first underground mining lights solution and purpose-built for hazardous mining environments. Meeting the growing need for robust, energy-efficient lighting alternatives in other harsh industrial sectors, Mineglow has expanded its presence with the widest range of tailor-made, premium-quality LED strip light solutions for mining and energy, tunnelling, construction, marine ports and conveyors.

Mineglow is the world’s largest distributor of x-Glo LED strip lighting.